For industrial solutions

- Maximum strength

- Optimal load distribution

- Virtually indestructible

- Sturdy, torsion-resistant lattice structure

Product Description

-

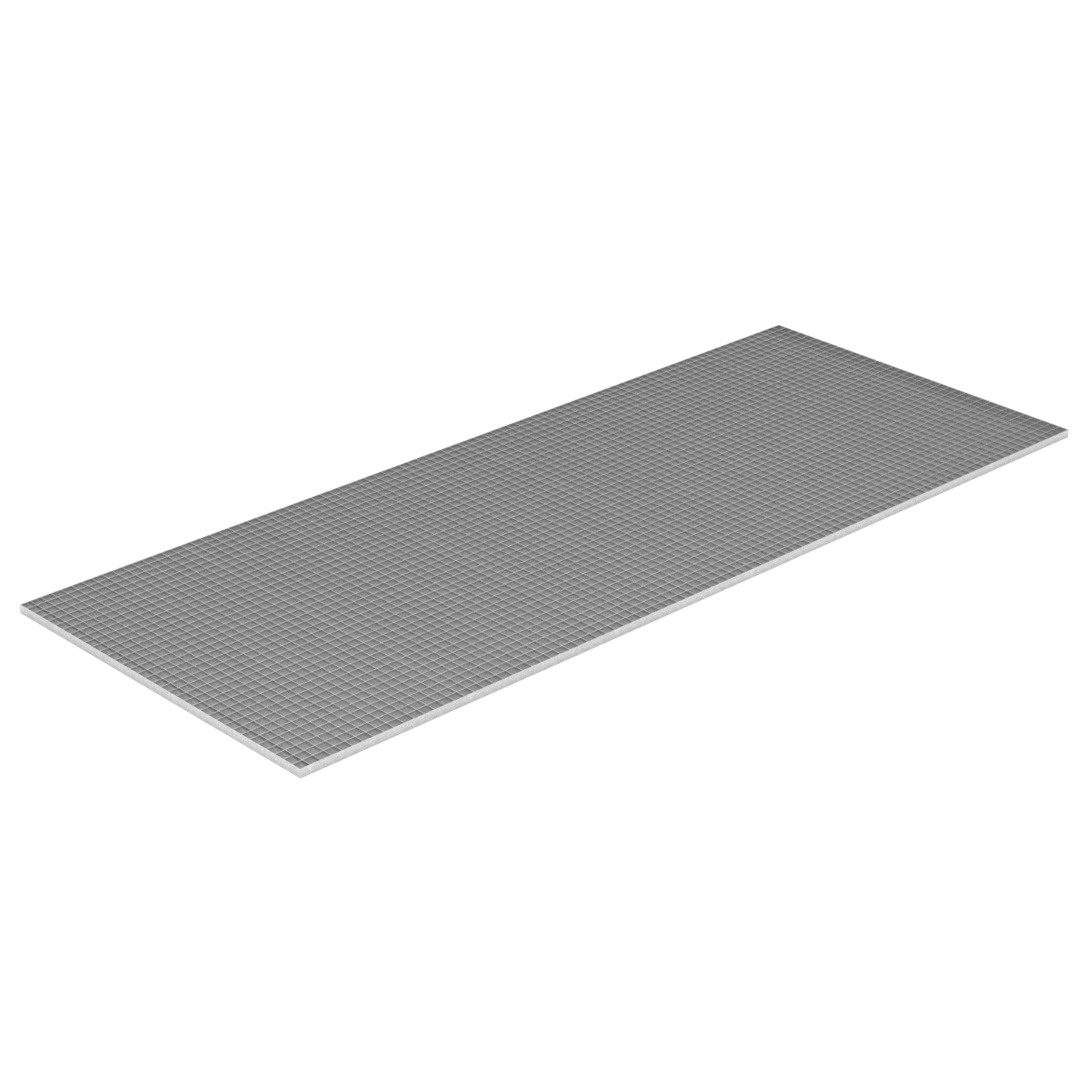

Grating mats – the standard for industry and the building trade

Modern construction sites would be unthinkable without gratings. They are used to create platforms and rostrums, bridge heights and fill gaps. Yet metal gratings play just as vital a part in industry as they do in the building trade. Quality and reliability are crucial, whatever the application. MEA is the acknowledged specialist for gratings. We have more than 50 years of experience as a manufacturer of premium-quality, galvanised or non-galvanised, pressure-locked and electro-welded gratings.

-

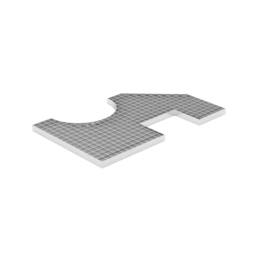

Optimal load distribution

MEA grating mats have a standard load bar length of 3 m and a torsion-resistant lattice structure. They combine maximum strength and durability with optimal load distribution.

-

Electro-welded gratings with an extra-rigid lattice structure

Electro-welded gratings are manufactured from S 235 JR steel and hot-dip galvanised by total immersion. Filling bars made from twisted square bar steel are force-fitted into full-strength load bars under high pressure and electrically welded in a single operation. Welding all intersections results in a flush grating surface and an extra-rigid lattice structure.

-

Standardised slip resistance

Any grating mat protects against slipping on platforms and gangways. MEA gratings are additionally inspected according to BGR 181 “Floors in workrooms and fields of activities with slip danger” and DIN 51130 “Testing of floor coverings”. Even in the most adverse conditions – where water and dirt or oils and greases are the norm – our grating mats ensure the highest levels of occupational safety on construction sites or in industry.

Germany:

English / English

Germany:

English / English