MEA gratings for all-in-one solutions

For several decades now, MEA Metal Applications has stood for competence and innovation when it comes to any aspect of gratings: our extensive product range includes not only standard solutions based on standard gratings but also special gratings in many different shapes and sizes – designed and built to meet each customer’s individual requirements. MEA gratings can be used anywhere in industry, logistics and architecture: they are proven in industrial facilities as well as in public or private buildings and in agriculture.

Quality from the manufacturer with many decades of experience in gratings

Founded in 1886 as a metalworking shop, MEA has been manufacturing gratings conforming to the highest quality standards since 1966. At MEA, comprehensive, all-in-one solutions take priority: MEA gratings offer countless design options, leave room for aesthetic considerations and allow numerous combinations with other materials. From staircases to platforms – planners and developers have (almost) endless possibilities to use gratings.

In-house galvanisation for top quality results

One essential part of producing gratings is ensuring that they are perfectly protected against corrosion. Hot-dip galvanisation guarantees optimal corrosion protection for steel – the gratings are durable, hard-wearing, maintenance-free and environmentally friendly, and they look good too. Once again, MEA can draw on several decades of experience and the expertise that comes from operating our own hot-dip galvanising plant.

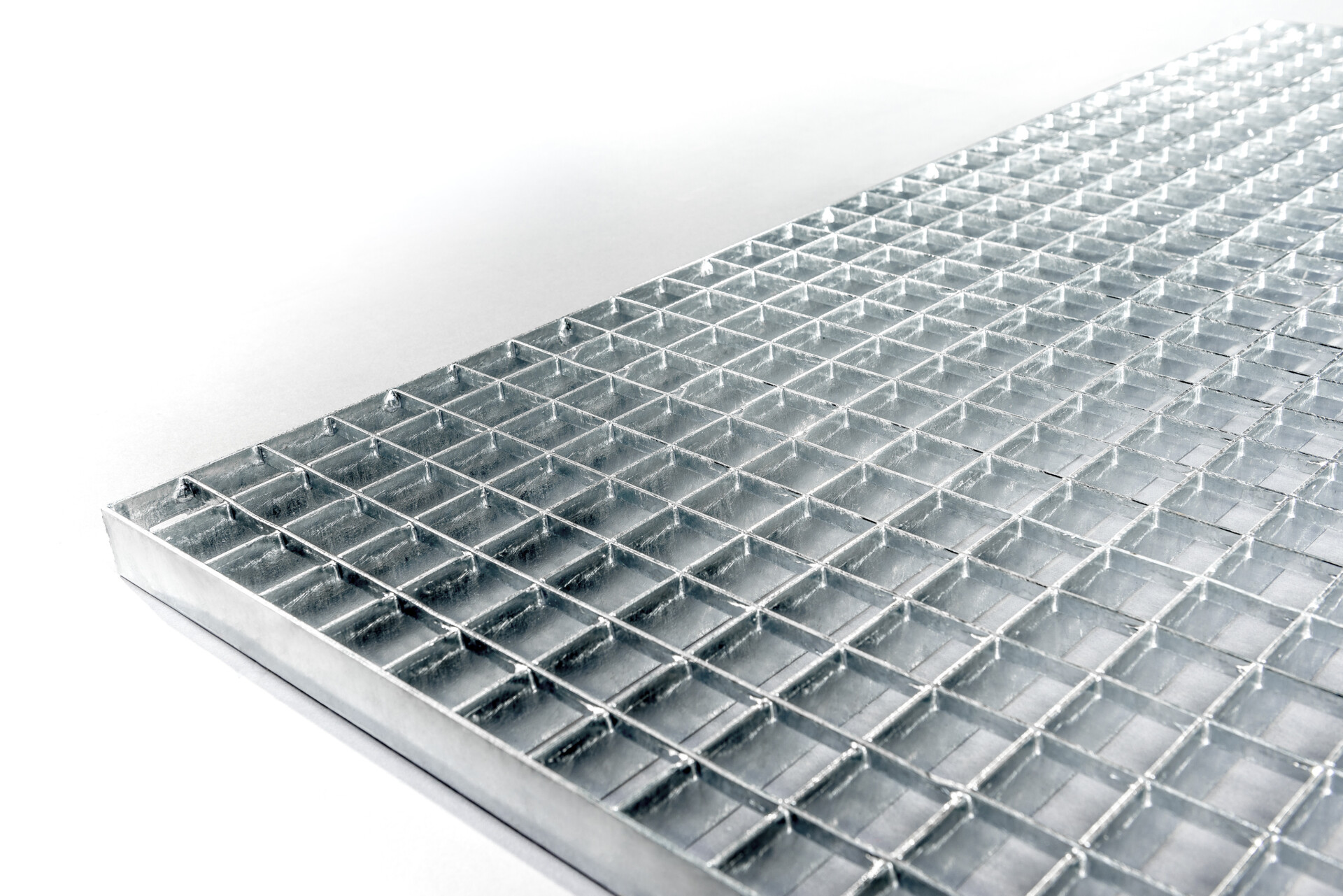

MEA pressure-locked gratings: the grating for staircases and more

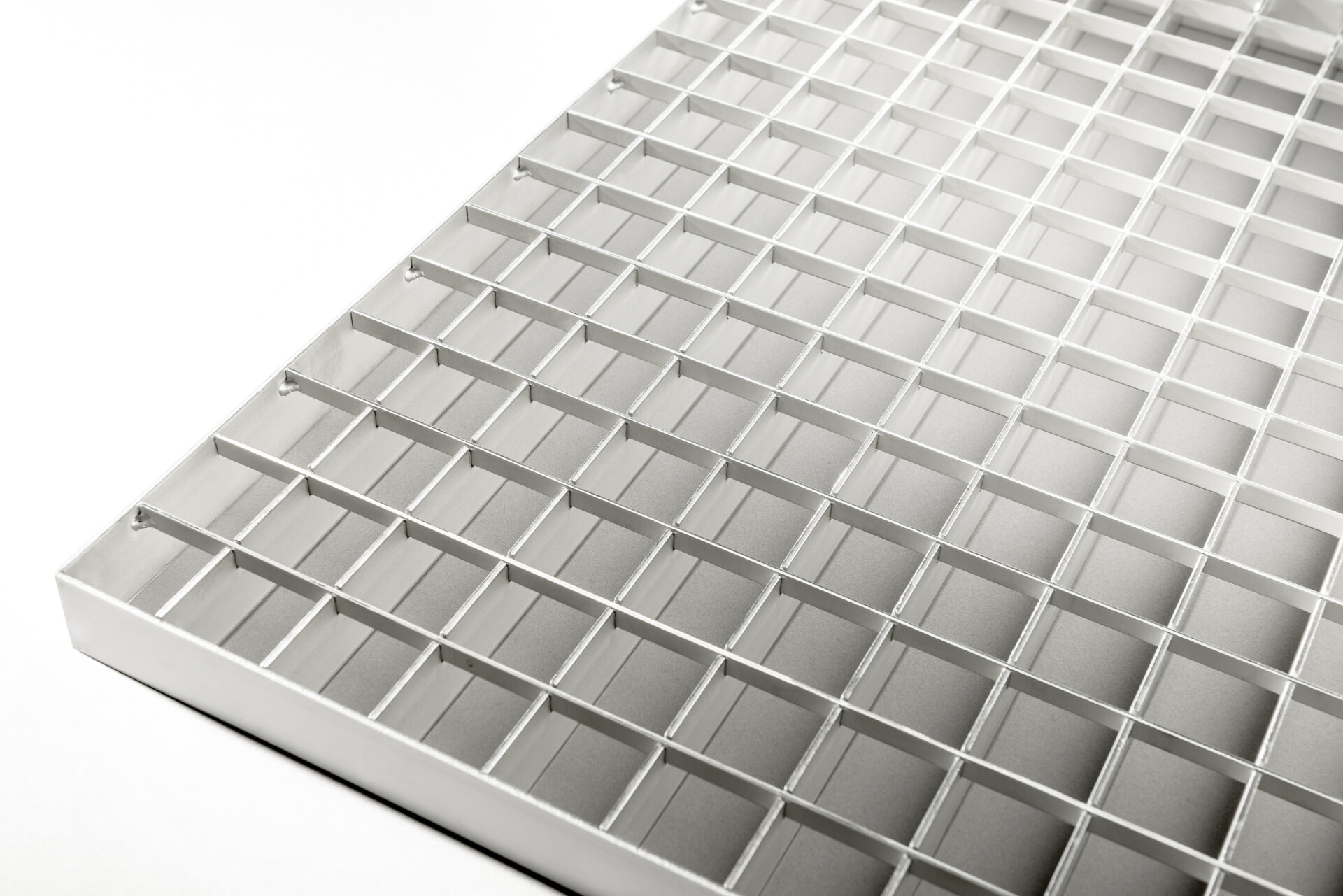

Pressure-locked gratings combine a flush surface and a precise, uniform mesh with a sturdy, torsion-resistant lattice structure. The load bars distribute the load between the supports while the filling bars are force-fitted into the load bars under high pressure, providing stability and ensuring that the load is distributed proportionally.

Flat steel rods are used for industrial or stair gratings and C-beam steel for standard gratings; our load and filling bars can also be manufactured in a slip-resistant design depending on the mesh combination.

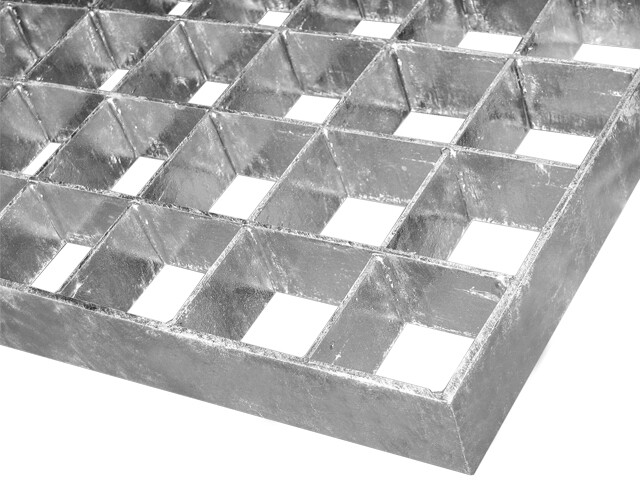

MEA full gratings: the universally usable grating

Full gratings are manufactured in the same way as pressure-locked gratings. Load and filling bars, of identical height and slotted through to the centre, are force-fitted into one another under high pressure. The admissible load capacity is equivalent to 80 per cent of that of pressure-locked gratings. When determining the load capacity of full gratings, please note that the load bars are the bars where both ends rest on the supporting substructure and which are not slotted on the underside.

Both sides of our full gratings have an identical surface, making them ideal for railing infills, facade cladding, suspended ceilings, partition walls and much more besides.

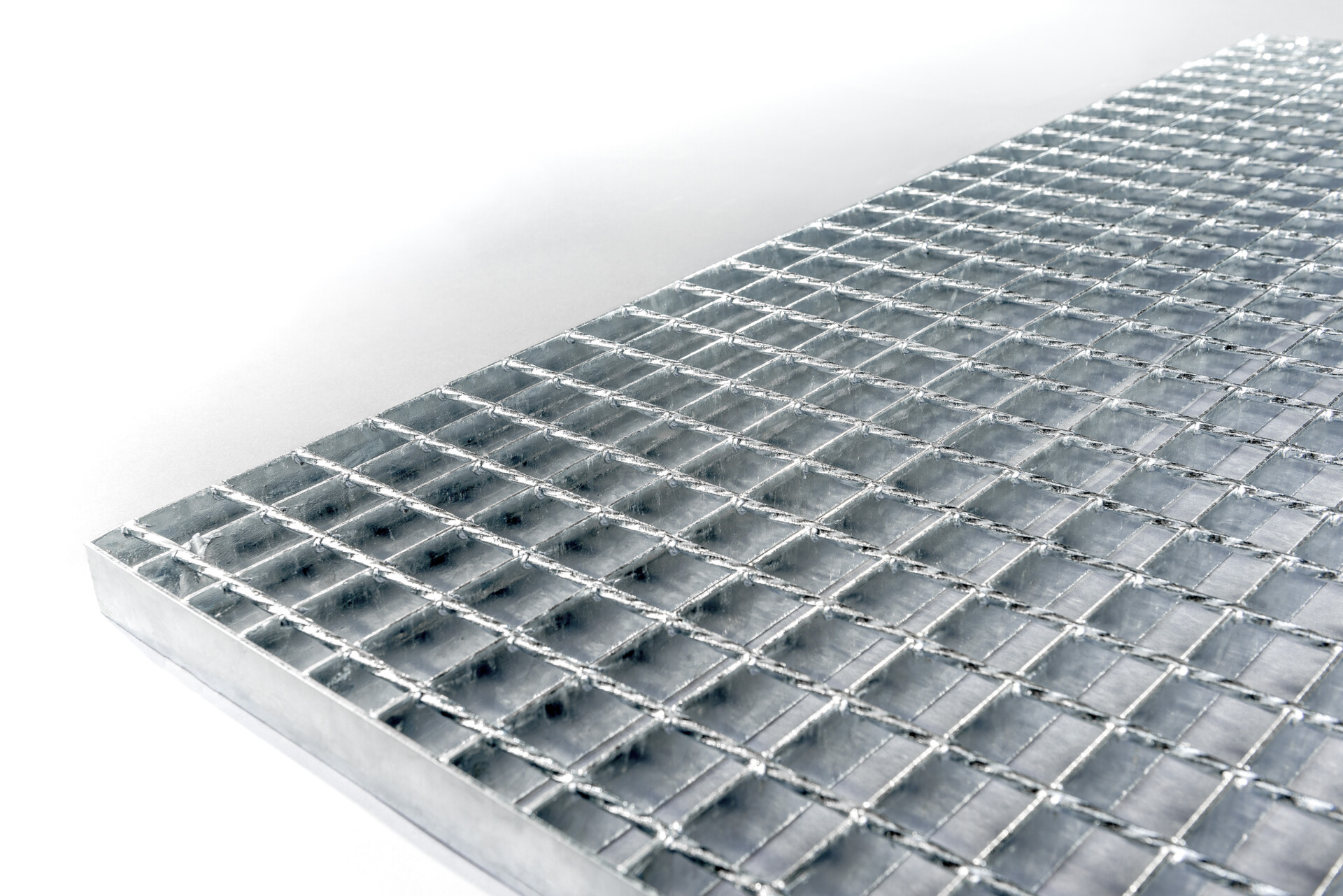

MEA electro-welded gratings: the maximum-strength grating

Electro-welded gratings are manufactured from S 235 JR steel and hot-dip galvanised by total immersion. Filling bars made from twisted square bar steel are force-fitted into full-strength load bars under high pressure and welded in a single operation. The fact that all intersections are fully welded results in a flush grating surface and a sturdy, torsion-resistant lattice structure combining maximum strength and durability with optimal load distribution. Our filling bars can also be manufactured in a slip-resistant design depending on the mesh combination.

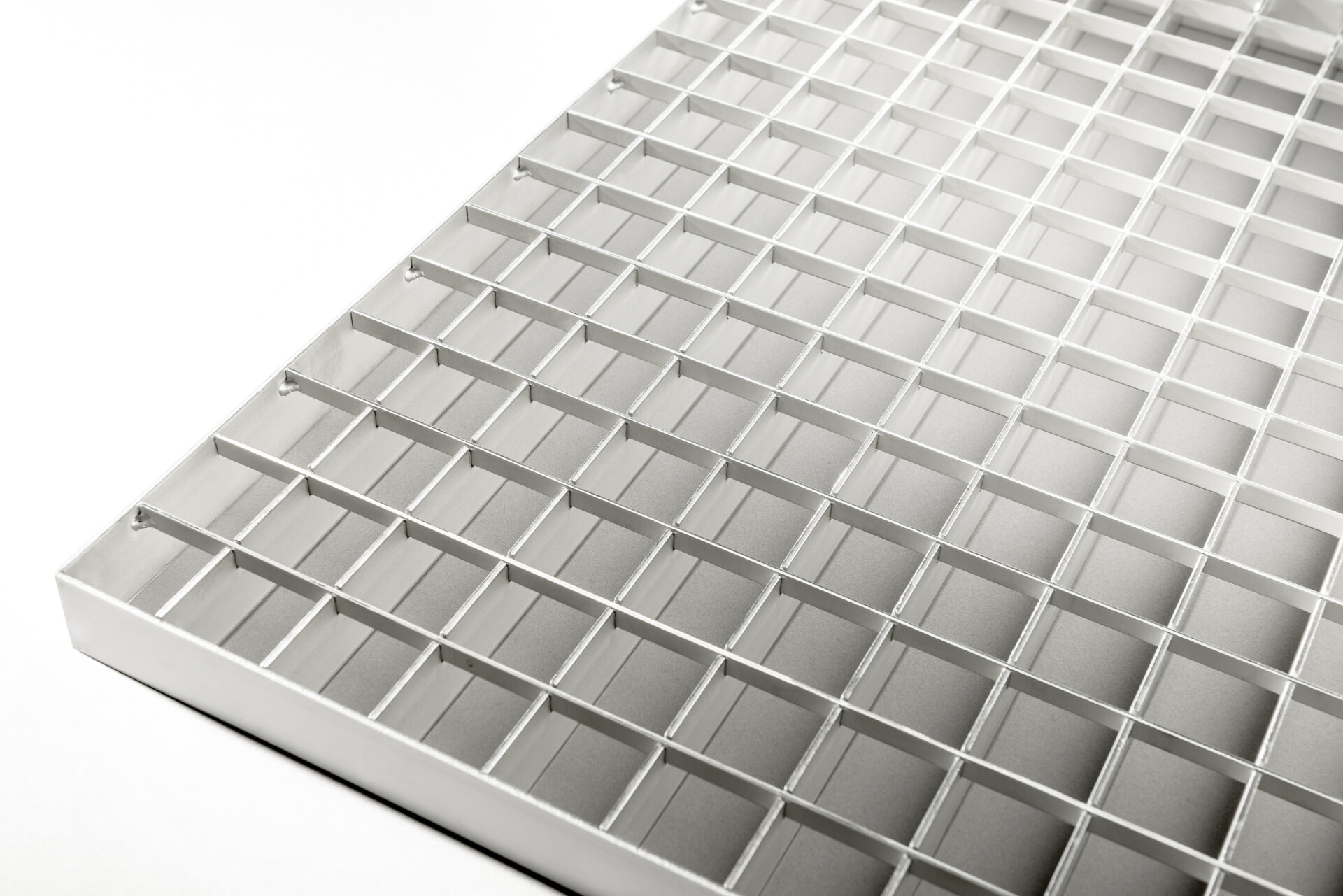

MEA stainless steel gratings: more than simply good to look at

MEA gratings manufactured from V2A or V4A stainless steels meet virtually any functional or material specifications demanded by customers. Rounded edges reduce the risk of injury and enable precise, smooth transitions.

MEA can also supply stainless steel gratings with a pickled or electro-polished surface on request. Whereas pickling results in a dull matte appearance, electro-polished gratings have a bright, chrome-like surface.

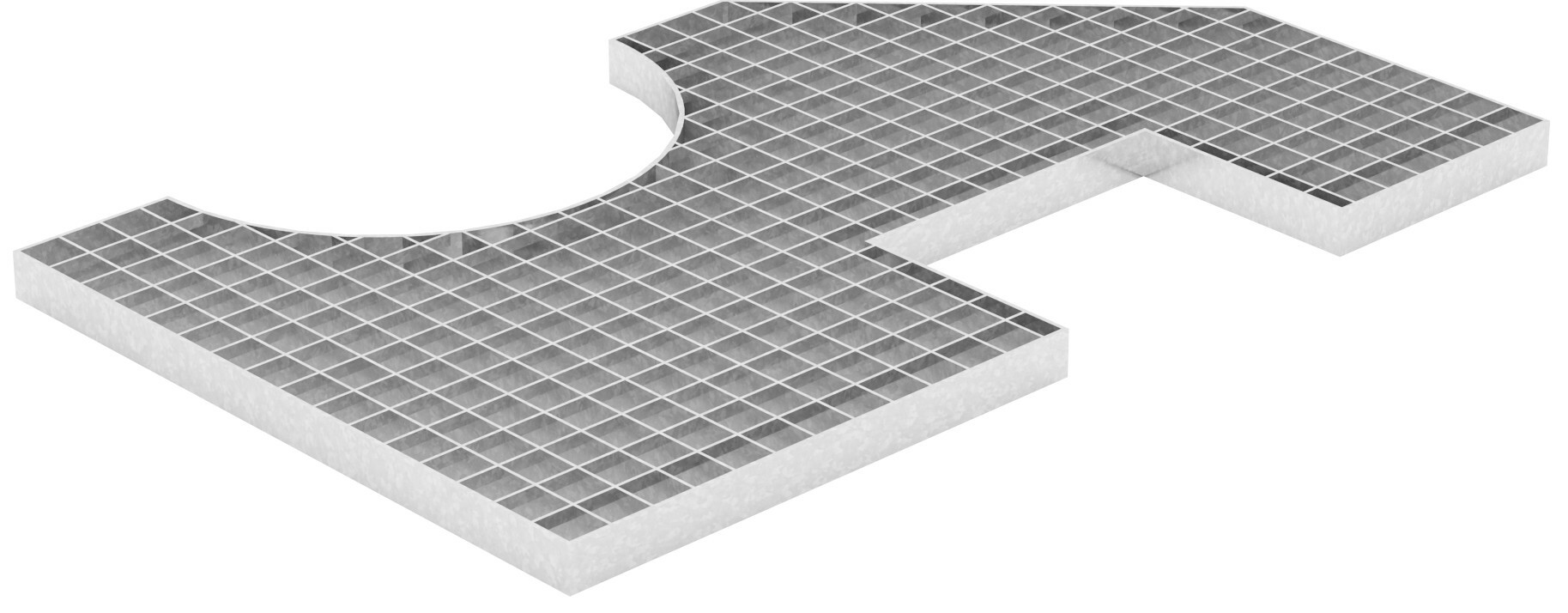

Made-to-measure gratings whatever the challenge

Complex buildings or structures demand custom solutions. Custom-built products with made-to-measure gratings are the norm for us, as are specific customer requirements regarding slip resistance, light falling in an unusual way or special mesh structures. Irrespective of the material and the method of production, MEA gratings are offered not only with different combinations of mesh and load bars but also in every conceivable size.

THE FULL SERVICE FROM SPECIFICATION TEXT TO ACCESSORIES

We can offer you extensive materials on our products in our download area: From product catalogues and price lists to CAD data, and from technical data sheets to installation and maintenance instructions, you will find important and helpful Information on the light well portfolio.

Discover our clever solutions for gratings

Made-to-measure gratings

Gratings made to measure: custom-made gratings individually built in steel or stainless steel by MEA, the manufacturer with many decades of experience.

stainless steel gratings

MEA stainless steel gratings are suited for a wide range of applications owing to their almost total resistance to a large number of substances. They are a very popular choice, for example, in the food processing industry, in breweries or in beverage manufacturing. Pharmaceutical and cosmetics producers also use stainless steel gratings in their plants and mechanical systems, as do all chemical corporations.

Germany:

English / English

Germany:

English / English